Fencing and Gates | Fencing Contractor

ASHTEAD, LEATHERHEAD, GUILDFORD, WOKING, ESHER, COBHAM, Dorking, Reigate, Redhill, Eastbourne, Brighton, Hove areas

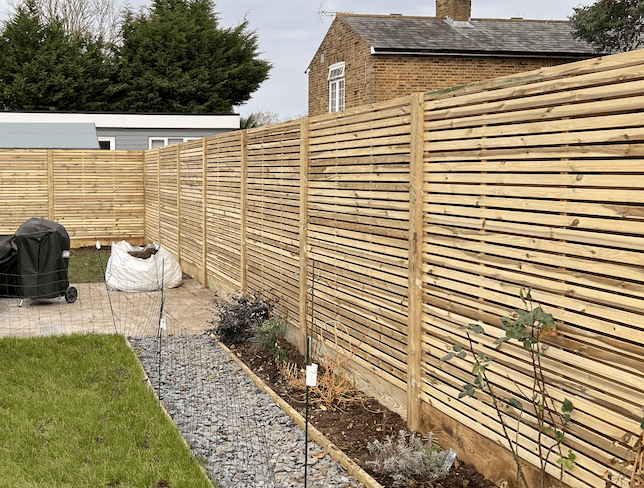

A strong, well-made fence is important for security, privacy and to create a boundary to your garden. But at Aye Landscape construction, we understand that a fence is more than that… it’s a frame for your whole landscaping project.

We’re fencing specialists with many years of experience installing a wide variety of fencing designs. Our expert team will help you choose the perfect fence for your garden, helping you to navigate the many styles, colours, materials and treatments available. So that you can be sure that you’ve chosen the perfect fence for your budget and property.

Fencing services

The Aye Landscape construction team can install your fencing along with any other structural elements in your garden, such as gates, sheds, pergolas, and arbours. Whether as a standalone installation, or as part of a larger landscaping project, we’ll take care of the whole process, including:

- a design consultation to help you firm up your ideas;

- explaining the different types of fencing and timber treatments available, so that you can make the right choice for you;

- advising on the style of your fencing, to make sure that it fits with the overall look of your garden as well as any neighbourhood requirements and regulations;

- suggesting planting ideas to make the most of your new fencing;

- discussion on complementing garden structures;

- sourcing your chosen materials;

- installation of your new fencing including access, and cooperation with neighbouring properties and boundaries;

- communication throughout the project.

Jacksons Fencing Approved Installer

Aye Landscape construction are proud to be a Jacksons Fencing Approved Installer, part of a nationwide network of landscaping professionals who Jacksons Fencing recommend and trust. As member of this network, we are committed to helping you keep your Jacksons Fencing products in excellent condition for years to come!

Jacksons have a unique ISO 9001 accredited process - Jakcure® - which allows preservative to penetrate deep into the timber through a combination of total immersion and vacuum pressure. Jacksons are so confident in their Jakcure® process that they give it a 25 year guarantee against all wood-boring pests and all forms of wet and dry rot. The timber needs no other treatment to keep its condition. Leaving you to spend more time relaxing in your garden!